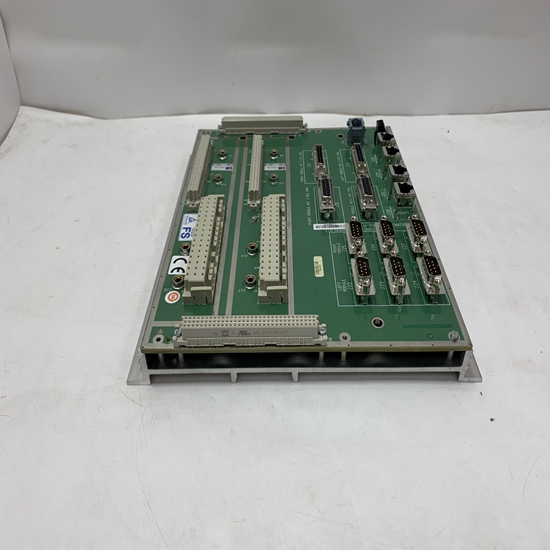

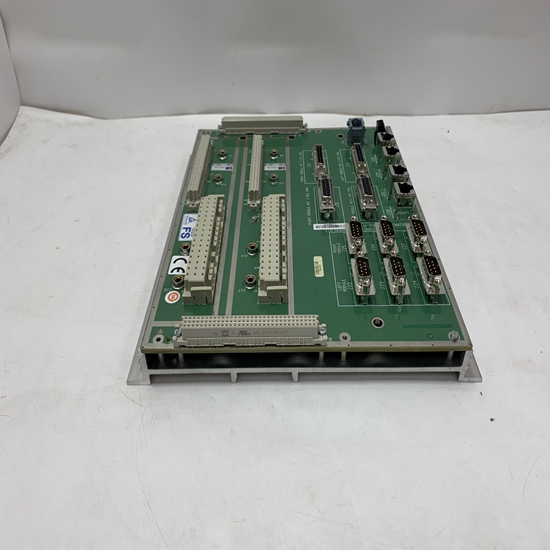

TRICONEX 9771-220 Interface Module

Product Description:

TRICONEX Interface Modules are specialized hardware units that provide the communication links between the TRICONEX safety controllers (like the Tricon or Tricon CX) and other critical systems. These can include Distributed Control Systems (DCS), Human-Machine Interfaces (HMI), field devices (sensors, actuators), and other PLCs. They are engineered to maintain the high integrity and availability characteristic of TRICONEX systems, often incorporating fault-tolerant designs to ensure continuous and safe operation.

Key Functions

- Data Exchange: Facilitate bidirectional exchange of process data and safety-critical information between the TRICONEX controller and external systems.

- Protocol Conversion: Translate data between the TRICONEX internal protocols (e.g., TriStation, TSAA, Fault Tolerant Ethernet - FTE) and common industrial communication protocols (e.g., Modbus TCP/IP, Modbus RTU, OPC, Profibus DP, FOUNDATION Fieldbus).

- Network Integration: Provide connectivity to various industrial networks, allowing for centralized monitoring, control, and data acquisition.

- Remote Access: Enable remote programming, diagnostics, and monitoring of the TRICONEX safety system.

- Fault Tolerance (for specific modules): Some interface modules, particularly communication modules (TCMs), are designed with redundancy (e.g., dual ports, internal redundancy) to maintain communication even if a component fails.

Product Parameters (Typical, varies by module type)

TRICONEX offers various interface modules, each with specific parameters. Examples include:

- Communication Protocols Supported: Ethernet (10/100 Mbps, including Fault Tolerant Ethernet), RS-232, RS-485, Modbus RTU, Modbus TCP/IP, OPC, Profibus DP, FOUNDATION Fieldbus, SNP/SNPX, TriStation, TSAA.

- Number of Ports: Varies depending on the module (e.g., 4 serial ports, 2 network ports for a Tricon Communication Module (TCM)).

- Port Isolation: Often includes electrical isolation (e.g., 500 VDC) for enhanced safety and noise immunity.

- Data Rates: Specific to the protocol (e.g., up to 115.2 Kbps for serial ports, 100 Mbps for Ethernet).

- Power Supply: Typically 24 VDC.

- Operating Temperature Range: Designed for harsh industrial environments, often -40°C to 85°C.

- Humidity Range: 5% to 95% non-condensing.

- Physical Form Factor: Modules are typically designed for rack mounting within a TRICONEX chassis.

- Compatibility: Specific modules are compatible with certain TRICONEX controller versions (e.g., Tricon v10.0 and later systems).

Product Advantages

- Enhanced Safety and Reliability: Crucial for safety instrumented systems (SIS), ensuring reliable data exchange to enable emergency shutdowns, fire and gas detection, and other critical safety functions.

- Fault Tolerance: Many modules incorporate redundant designs (e.g., Triple Modular Redundancy - TMR principles in underlying systems, or redundant communication paths) to eliminate single points of failure and ensure continuous operation.

- Seamless Integration: Designed to integrate smoothly with TRICONEX controllers and a wide range of external systems (DCS, HMI, field devices) via various industry-standard protocols.

- High Performance: Enables fast and reliable data exchange, which is essential for timely response in safety-critical applications.

- Robust Diagnostics: Often include comprehensive diagnostic capabilities to quickly detect and isolate faults, minimizing downtime and simplifying maintenance.

- Online Replacement Capability: In many TRICONEX systems, modules can be replaced online without interrupting the process, further enhancing availability and reducing downtime.

- Compliance: Designed to meet stringent international safety standards like IEC 61508.

Precautions

- System Compatibility: Always verify the specific module's compatibility with the TRICONEX controller version and other system components.

- Proper Configuration: Correct configuration of communication parameters (IP addresses, subnet masks, serial port settings, protocol settings) is essential for successful operation.

- Environmental Limits: Ensure the operating environment (temperature, humidity, vibration) remains within the module's specified limits to prevent malfunction.

- ESD Protection: As with all electronic components, handle interface modules with proper electrostatic discharge (ESD) precautions.

- Correct Wiring: Follow precise wiring diagrams and best practices to ensure proper signal integrity, prevent electrical noise, and maintain safety. Use appropriate shielding for communication cables where specified.

- Firmware Updates: Keep module firmware updated according to manufacturer recommendations to ensure optimal performance, security, and compatibility.

- Documentation: Always refer to the official TRICONEX product manuals and safety considerations guides for detailed installation, operation, and maintenance instructions.

Product Applications

TRICONEX Interface Modules are fundamental to the operation of TRICONEX Safety Instrumented Systems (SIS) across numerous high-hazard industries, including:

- Oil & Gas: Emergency Shutdown Systems (ESD), Fire and Gas (F&G) detection, High-Integrity Pressure Protection Systems (HIPPS), pipeline control.

- Chemical & Petrochemical: Process safety interlocks, reactor control, hazardous material handling.

- Power Generation: Burner Management Systems (BMS), turbine control and protection, boiler protection.

- Mining: Safety systems for heavy machinery and material handling.

- Pharmaceutical: Process safety and validation in drug manufacturing.

- Water & Wastewater: Critical safety interlocks for pump stations and treatment processes.

The structure and details of the product:

Our services:

Shipping Port: China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Warranty: one year

Please make an inquiry for more models:

TRICONEX 3625

TRICONEX 3720

TRICONEX AI3351

TRICONEX 3006

TRICONEX 3503E

TRICONEX 3604E

TRICONEX 3700

TRICONEX 3700A

TRICONEX 4328

TRICONEX 4351B

TRICONEX 3625C1

TRICONEX 3721

TRICONEX 3805E

TRICONEX 4329

TRICONEX 8312

TRICONEX AI2351

TRICONEX 3008

TRICONEX 3805H

TRICONEX 9563-810

TRICONEX 3664

TRICONEX 3000520-380

TRICONEX 4000094-310

TRICONEX 3504E

TRICONEX 8111

TRICONEX 3625A

TRICONEX 3000470-510

TRICONEX 3623T

TRICONEX DO3401

TRICONEX 3636R

TRICONEX 3201

TRICONEX 3625C

TRICONEX 3501E

TRICONEX 8110

TRICONEX 3511

TRICONEX 3501T

TRICONEX DI3301

TRICONEX 3704E

TRICONEX 30005

TRICONEX 8310

TRICONEX D03401

TRICONEX 4351A

TRICONEX 3601E

TRICONEX 3009

TRICONEX 3504E

JUSTWELL PTE. LTD. sells new and discontinued products, and purchases such specialty products through independent channels. JUSTWELL PTE. LTD. is not an authorized distributor, distributor, or representative of the featured products on this website. All product names/images, trademarks, brands, and logos used on this website are the property of their respective owners. Product descriptions, descriptions, or sales with these name images, trademarks, brands, and logos are for identification purposes only and do not imply any association or authorization with any rights holders.

This article is from the official website of JUSTWELL PTE. LTD. If reprinted, please attach this link: https://justwellltd.com .com

JUSTWELL PTE. LTD

Our main products include DCS control system spare parts, PLC system spare parts, and robot system spare parts. Our advantageous brands include Allen Bradley, Bently Nevada, ABB, HIMA, Reliance, Bender, National Instruments, Emerson Ovation, Honeywell, Siemens, Allen Bradley, ICS Triplex, FOXBORO, Schneider, GE Fanuc, Motorola, HIMA, Prosoft, and other imported industrial components. Our main products serve a wide range of electronic, metallurgical, chemical, and power plants Industries such as steel mills, rubber, cement, machinery and equipment, and construction.