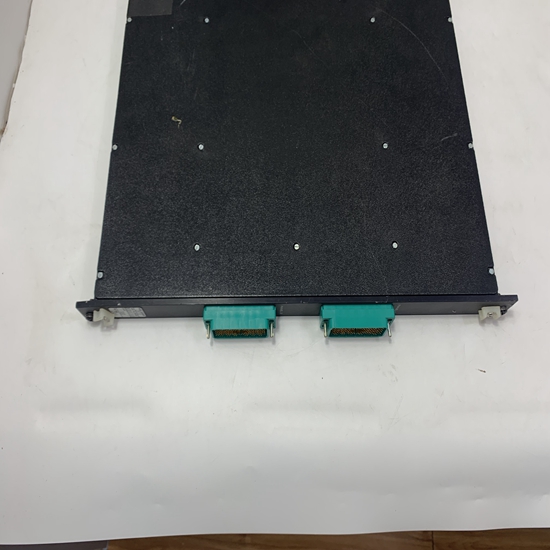

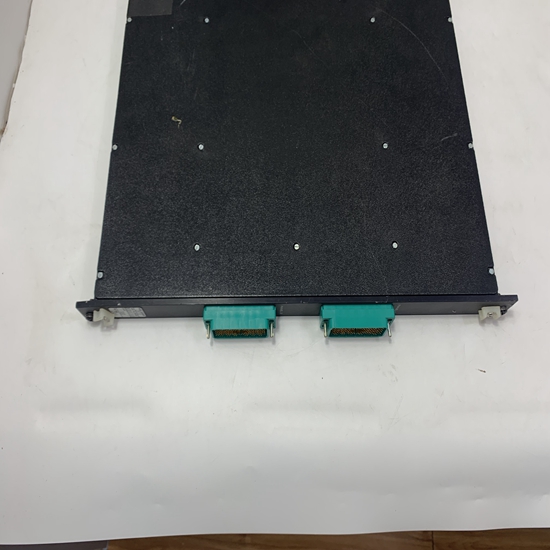

TRICONEX 3000270-300 Communication Processor

Product Description:

TRICONEX Communication Processors (often referred to as Communication Modules or TCMs) facilitate the secure and reliable transfer of data between the Triple Modular Redundant (TMR) main processors of a TRICONEX system and external systems. They act as the communication gateway, handling various industrial protocols and ensuring data integrity and availability, even in the event of component failures. Their design emphasizes fault tolerance and diagnostic capabilities, which are paramount for maintaining the safety and continuous operation of critical industrial processes.

Key Functions

- Protocol Conversion: Translates data between the internal TRICONEX TMR architecture and external communication protocols (e.g., Modbus, Ethernet/IP, OPC, peer-to-peer).

- Data Exchange: Enables bidirectional data flow for process variables, diagnostic information, alarms, and control commands.

- Network Integration: Provides connectivity to Distributed Control Systems (DCS), SCADA systems, HMIs, and other plant-wide networks.

- Fault-Tolerant Communication: Incorporates redundant communication paths and sophisticated error checking to ensure data delivery even if a single communication component fails.

- Time Synchronization: Facilitates accurate time synchronization across the entire safety system and connected devices.

- Diagnostics: Provides comprehensive diagnostics for communication status, network health, and module integrity.

Product Parameters (Typical)

Parameters can vary significantly between specific TRICONEX Communication Processor models (e.g., TCM 4351B, TCM 4352AN, TCM 4355X, CM3201S2). However, common parameters include:

- Supported Protocols: Ethernet (Modbus TCP/IP, OPC UA, EtherNet/IP, Fault Tolerant Ethernet - FTE), Serial (RS-232, RS-485, Modbus RTU, SNP/SNPX).

- Network Ports: Number and type of ports (e.g., RJ45 for Ethernet, DB9 for serial, fiber optic options via SFP devices).

- Data Rates: Typical Ethernet speeds are 100BASE-TX/FX or 1000BASE-T/X. Serial speeds up to 115.2 Kbps per port.

- Isolation: Galvanic isolation between ports and from the backplane for noise immunity and safety (e.g., 500 VDC).

- Processor: Dedicated communication processor (e.g., Intel 80C152, 16 MHz) with dedicated memory (e.g., 32 KB EPROM, 64 KB shared memory).

- Power Consumption: Typically low, varying by module.

- Operating Temperature: Wide industrial range (e.g., -40°C to +70°C).

- Humidity: 5% to 95% relative humidity, non-condensing.

- Dimensions & Weight: Standard module form factor for TRICONEX chassis.

Product Advantages

- High Availability & Reliability: Built on TRICONEX's patented Triple Modular Redundant (TMR) architecture, providing inherent fault tolerance and continuous operation even with multiple hardware failures. This is critical for safety-instrumented systems.

- Enhanced Safety: Contributes to the overall safety integrity of the system by ensuring reliable and deterministic data flow, often certified up to Safety Integrity Level (SIL) 3 according to IEC 61508.

- Seamless Integration: Designed to integrate effortlessly with other TRICONEX system components (Main Processors, I/O modules, power supplies) and a wide array of external systems.

- Comprehensive Diagnostics: Extensive self-diagnostics continuously monitor the module's health, communication status, and network integrity, allowing for early detection and reporting of faults.

- Online Maintenance: Supports hot-swappable module replacement and online configuration changes without interrupting the process, maximizing plant uptime.

- Cybersecurity Features: Newer modules incorporate features to enhance cybersecurity, critical for protecting industrial control systems from cyber threats.

- Scalability: Can be used in systems ranging from small, localized applications to large, distributed industrial complexes.

Precautions

- Compatibility: Always verify module compatibility with the specific TRICONEX system version (firmware and hardware) to ensure proper operation and maintain safety certifications.

- Configuration: Precise configuration of communication parameters (IP addresses, subnet masks, baud rates, protocols, etc.) is critical for establishing and maintaining reliable communication.

- Wiring Practices: Adhere strictly to TRICONEX's wiring guidelines for industrial environments, including proper shielding, grounding, and cable routing, to minimize electromagnetic interference (EMI) and ensure signal integrity.

- ESD Protection: Always follow Electrostatic Discharge (ESD) precautions when handling modules to prevent damage to sensitive electronic components.

- Environmental Conditions: Ensure the operating environment stays within the specified temperature, humidity, and vibration limits to prevent premature module failure.

- Security: Implement network segmentation, access controls, and other cybersecurity best practices as recommended by TRICONEX/Schneider Electric to protect the safety network from unauthorized access and cyberattacks. Regularly update firmware when available and after proper testing.

- Documentation: Refer to the specific TRICONEX module's product manual for detailed installation, configuration, and troubleshooting information.

Product Applications

TRICONEX Communication Processors are indispensable in industries where safety, reliability, and continuous operation are paramount. Their applications include:

- Oil & Gas (Upstream, Midstream, Downstream): Emergency Shutdown Systems (ESD), Fire & Gas (F&G) Systems, Burner Management Systems (BMS), Wellhead control.

- Chemical and Petrochemical: Process safety, critical control loops, reactor protection.

- Power Generation: Turbine control, boiler protection, balance of plant safety systems.

- Pharmaceuticals: Process validation, critical utility control.

- Mining & Metals: Safety interlocking, emergency stops for heavy machinery.

- Water & Wastewater: Critical pumping station control, treatment plant safety.

Typical Applications

- Integrating a TRICONEX ESD system with a plant's DCS: The communication processor enables the DCS to monitor the status of the safety system and receive critical alarm data, while also allowing safe data transfer for non-safety-critical information.

- Connecting a TRICONEX F&G system to a central HMI: Allows operators to visualize gas detection levels, fire zone status, and activate emergency response procedures.

- Providing remote diagnostics and asset management: Enables engineers to access system health information, event logs, and diagnostic data from a remote workstation for predictive maintenance and troubleshooting.

- Facilitating peer-to-peer communication between multiple TRICONEX chassis: In large-scale applications, communication processors allow distributed TRICONEX systems to exchange safety-critical information directly.

The structure and details of the product:

Our services:

Shipping Port: China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Warranty: one year

Please make an inquiry for more models:

TRICONEX 3625

TRICONEX 3720

TRICONEX AI3351

TRICONEX 3006

TRICONEX 3503E

TRICONEX 3604E

TRICONEX 3700

TRICONEX 3700A

TRICONEX 4328

TRICONEX 4351B

TRICONEX 3625C1

TRICONEX 3721

TRICONEX 3805E

TRICONEX 4329

TRICONEX 8312

TRICONEX AI2351

TRICONEX 3008

TRICONEX 3805H

TRICONEX 9563-810

TRICONEX 3664

TRICONEX 3000520-380

TRICONEX 4000094-310

TRICONEX 3504E

TRICONEX 8111

TRICONEX 3625A

TRICONEX 3000470-510

TRICONEX 3623T

TRICONEX DO3401

TRICONEX 3636R

TRICONEX 3201

TRICONEX 3625C

TRICONEX 3501E

TRICONEX 8110

TRICONEX 3511

TRICONEX 3501T

TRICONEX DI3301

TRICONEX 3704E

TRICONEX 30005

TRICONEX 8310

TRICONEX D03401

TRICONEX 4351A

TRICONEX 3601E

TRICONEX 3009

TRICONEX 3504E

JUSTWELL PTE. LTD. sells new and discontinued products, and purchases such specialty products through independent channels. JUSTWELL PTE. LTD. is not an authorized distributor, distributor, or representative of the featured products on this website. All product names/images, trademarks, brands, and logos used on this website are the property of their respective owners. Product descriptions, descriptions, or sales with these name images, trademarks, brands, and logos are for identification purposes only and do not imply any association or authorization with any rights holders.

This article is from the official website of JUSTWELL PTE. LTD. If reprinted, please attach this link: https://justwellltd.com .com

JUSTWELL PTE. LTD

Our main products include DCS control system spare parts, PLC system spare parts, and robot system spare parts. Our advantageous brands include Allen Bradley, Bently Nevada, ABB, HIMA, Reliance, Bender, National Instruments, Emerson Ovation, Honeywell, Siemens, Allen Bradley, ICS Triplex, FOXBORO, Schneider, GE Fanuc, Motorola, HIMA, Prosoft, and other imported industrial components. Our main products serve a wide range of electronic, metallurgical, chemical, and power plants Industries such as steel mills, rubber, cement, machinery and equipment, and construction.